Summary

Business Case

Every year, large-scale shipping and manufacturing lose tens-of-millions of euros to lost or stolen assets — trolleys, containers, and rollcages that carry the supply chain from order to delivery.

HERE Technologies, a global giant in location technology services, were equipped to solve this — and engineered a cutting-edge IoT hardware solution these shippers could attach to their high-value assets; connecting them to a software platform to both chart their assets across the globe in realtime, forecast and optimise their utilisation.

My Role

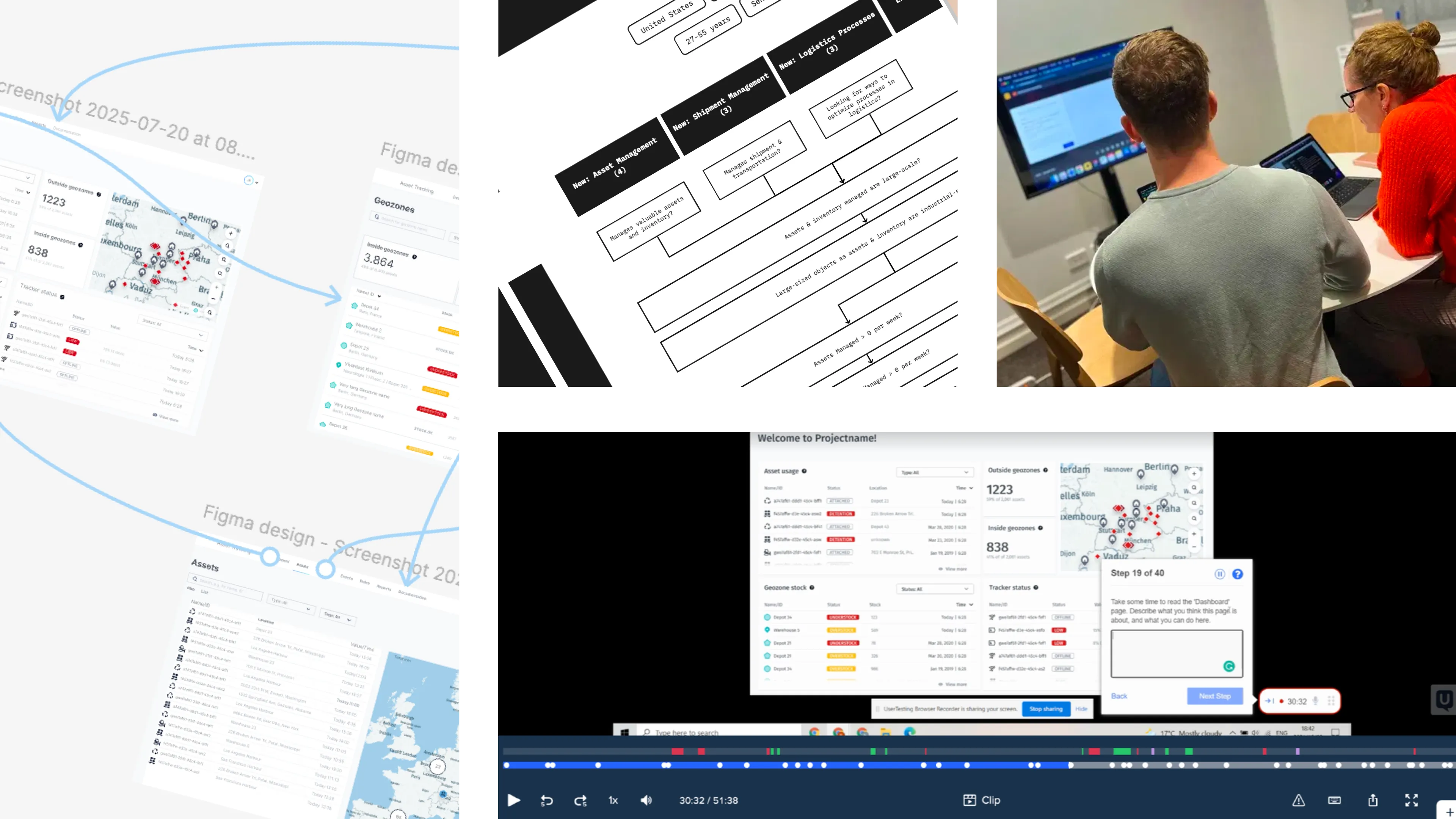

Onboarding into this new team, my role as the Lead Designer, reporting directly to the Head of PM, was to collaborate with Engineering, Sales, Marketing leads to realise an interactive prototype; an embodiment of a great hypothesis formed from months of stealthy market research; ready for its first encounter with real users.

User Profile

Supply Chain Managers coordinate the first and last leg of the middle-mile in the supply chain: comprised of the land journeys:

- from warehouse to port of departure

- from port of arrival to depot.

This means being in constant contact with suppliers, transporters, logistics centre and maritime transport operators to locate assets, balance inventory, and optimise the flow of goods. More often than not, asset tracking means using outdated and disconnected systems — phone calls, speadsheets, and ERPs — slow, offline, and fraught with error, risking massive company loss.

Product Vision

This presented an opportunity to build a single, unified view comprised of interconnected, multi-layered data feeds that tell the holistic story of realtime supply chain journey, to help these experts make intelligent executive decisions from.

Project Journey

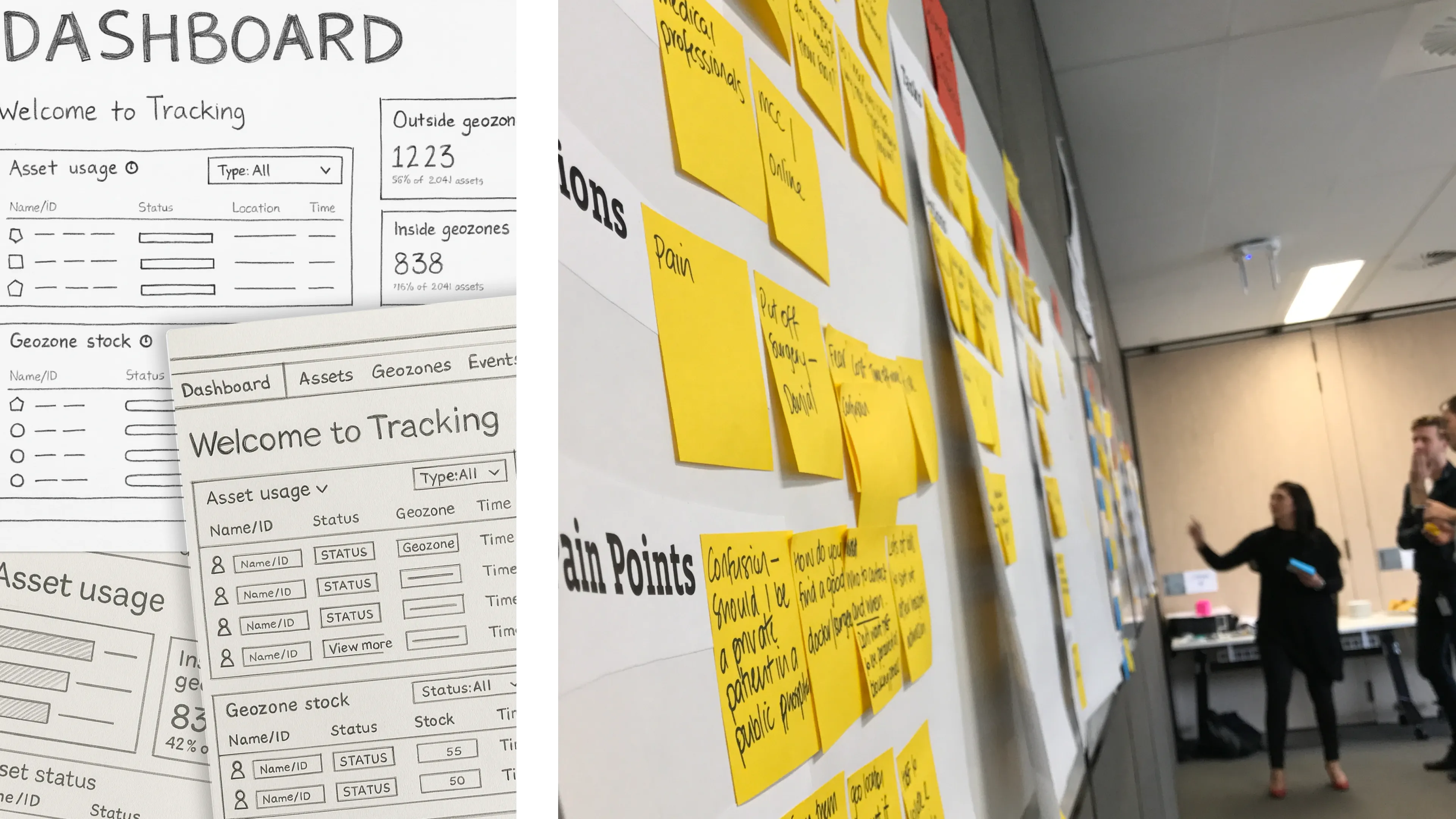

Working with a complex subject matter, with great ambitions, in an ambiguous product state, as a new joiner; can easily paralyse a project’s progress. To fight off these four-horseman, I leant on the following principles:

- Process-driven Design: How you get there is more important than where you ended up.

- Better together: Leverage the team’s wisdom, and diversity to build trust, and a better solution faster.

- Lean, Launch and Learn: Build and release in short cycles, and work towards incremental improvements, not perfection.

The above meant phrasing the work over a series of short sprints spanning problem discovery interviews with the team, to solution co-design workshops, to rapid prototype development, through to deploying to user testing for group synthesis.

Design Solution

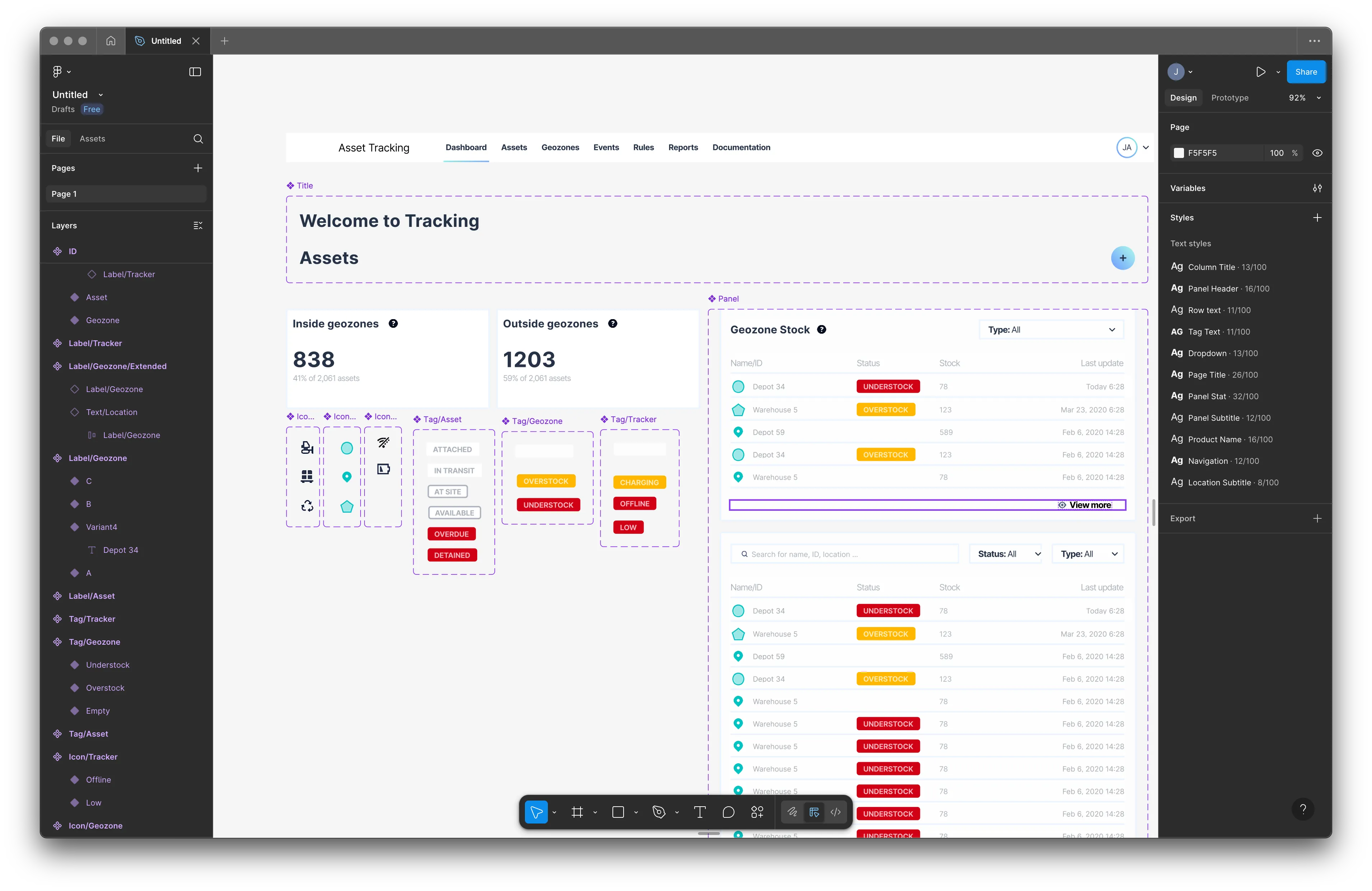

Leveraging the HERE Design System gave me on-brand, usability-tested assurance that enabled me to sprint from sketched wireframes in the co-design workshop to interactive prototype in a matter of days.

Multi-modal Thinking

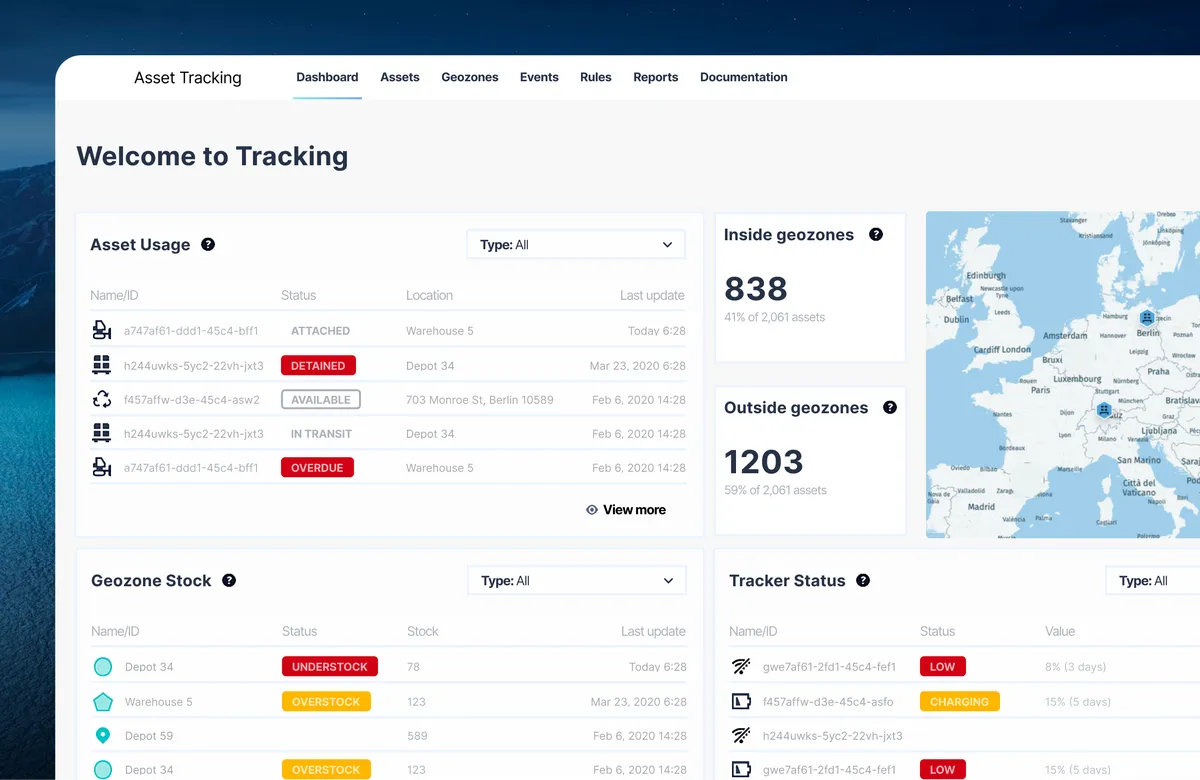

The dashboard is divided into panels representative of the 3 different mental modes a Supply Chain Manager needs to think in:

- Asset Usage; to assess if critical mobile assets are missing, detained or off-course

- Geozone Stock: to forecast and rebalance asset stock between depots to prevent production bottlenecks

- Tracker Status: to detect tracker performance issues early to avoid data blind spots

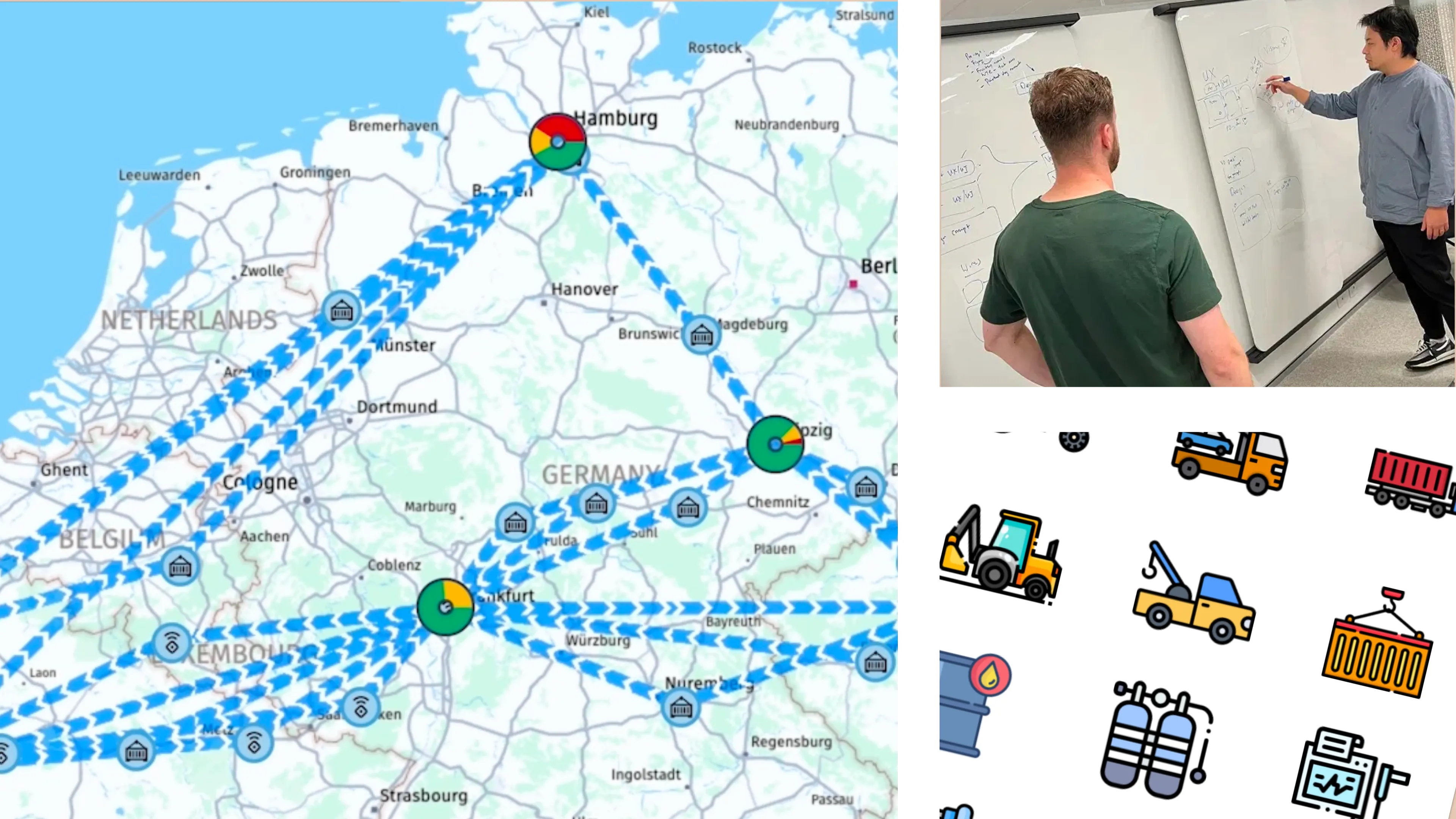

Equally important is the ability to switch between tabular and geo-spatial views to make sense of the data.

![]()

Exception Handling

When you consider the 1000’s of possible assets to track, multiplied by its infinite states and events, prioritising attention on the most critical issues, and nothing more, is paramount. From the F shaped layout, to the spartan colour coding, to the minimal iconography — all are designed to spare attention, until exceptional cases require action.

![]()

Progressive Drilldown

Analytical users like ours need to be able to move from summary to specifics quickly. Filter, sort, and search controls in the table, and clustered nodes on the map, not only afford dashboard performance, but expert users a playground to explore and crunch the data frame-by-frame.

![]()

Validation & Impact

3 rounds of 15 participants in a remote moderated usability study of our 3-screen prototype hosted on UserTesting.com revealed 2 critical flaws, and invalidated an assumed feature, the impact of which won the team 4-weeks of time developing a non-feature we reinvested in validated features.

- Missing Vernacular: Our European number formattings, terms like ‘Geozones’, and statuses like ‘demurrage’, and more were lost on our largely US test audience; resulting in strategic conversations amongst leadership on which markets to design for first, and localisation efforts.

- Geozone/Tracker Updates: we were surprised to learn how many of our testers (25/45) misunderstood Geozones, and the Tracker timestamps — a trend that suggested the slow adoption/readiness of IoT hardware like ours in the industry. The outcome of this fed conversations within leadership on refining our customer profile.

- Table-first Layout: We underestimated the importance of the map component on the dashboard as the primary mental model for our users; resulting in abandoning the development of advanced table controls, for a pivot to a map-first layout that defines the product to this day

Retrospective

- Learning 1: Dashboards are hyper-contextual products; and building prototypes with foreign, static data is difficult to immerse users necessary to gather reliable feedback. Next time, I’d generate a coded prototype with AI, and rapidly iterate on it every 5 user tests until we get diminishing returns. I might even load 2 sets of different domain data (e.g. manufacturing, mining) into the prototype, and pair users corresponding to those industries.

- Learning 2: Supply Chain Managers, and B2B users in general, are hard won research participants. It’s important to build relationships with them, and regularly engage them in the design process. While my work also included building a repeatable design-testing framework and repository of these participants, I would rally more across other product areas and business units to make recruitment a company sport.